ISRO tests fuel cell to potentially power space missions

- The Indian Space Research Organisation (ISRO) has achieved a milestone by successfully demonstrating a fuel cell in space.

The Experiment

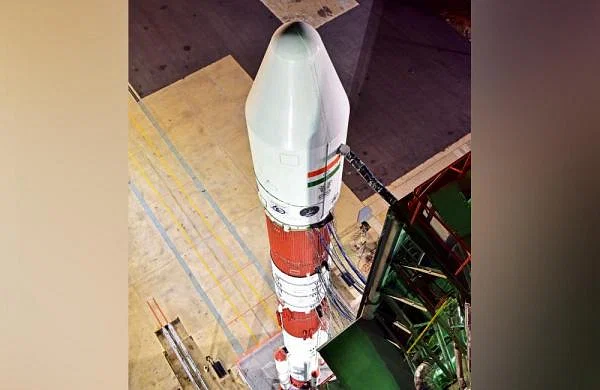

- ISRO tested a 100 W class Polymer Electrolyte Membrane Fuel Cell based Power System (FCPS) on its orbital platform, POEM3.

- Objective: To assess the operation of Polymer Electrolyte Membrane Fuel cells in space and gather data for designing systems for future missions.

- The fuel cell, deployed on the fourth stage of the PSLV, generated 180W of power during a brief test.

- The fuel cell, developed by the Vikram Sarabhai Space Centre (VSSC), serves as a precursor to future power systems for space stations.

Polymer Electrolyte Membrane (PEM) Fuel Cells

- Also known as proton exchange membrane fuel cells, they are electrochemical devices that convert chemical energy into electrical energy.

- They use a proton-conducting polymer membrane as the electrolyte and typically use hydrogen as the fuel.

Significance of Fuel Cells

- Fuel Cells utilise hydrogen and oxygen to generate electricity while producing heat and water as byproducts.

- These are deemed ideal for human space missions due to the dual benefits of generating power and essential byproducts like heat and water.

- This integrated system can cater to multiple mission requirements simultaneously.

- They produce electricity directly and are efficient, emission-free, and ideal for space missions.

- The zero-emission fuel cells may find applications on Earth as potential replacements for vehicle engines.

Silicon-based Cell

- ISRO also successfully demonstrated a Silicon-based cell developed by VSSC, offering a cost-effective and lighter alternative to current cells.

- This innovation utilizes a silicon-graphite composite, providing higher energy generation per unit weight compared to conventional Li-ion cells.

Operational Missions and Mass Saving

- The demonstrated fuel cell is expected to be utilized in upcoming operational missions, offering a significant battery mass saving of 35-40%.

- The design incorporates cost-effective hardware and a crimped sealing mechanism, reducing fabrication costs.

Prelims Takeaway

- Fuel Cells

- Polymer Electrolyte Membrane (PEM) Fuel Cells